Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins.The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time can be available upon request.

Powder Chopped Strand Mats:

Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins.The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time can be available upon request.

![]()

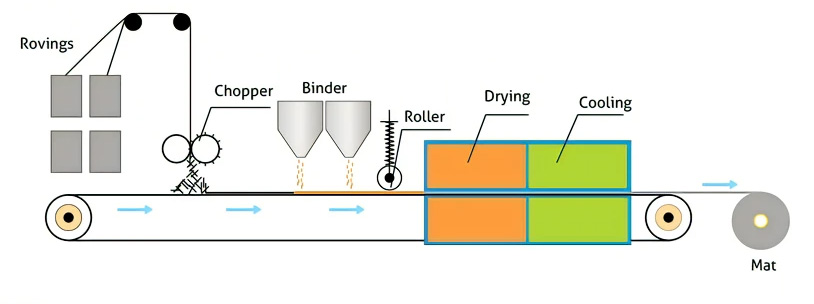

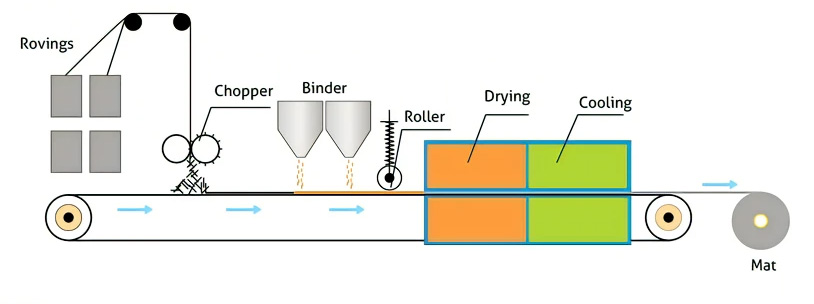

Mat Production Process:

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

![]()

1. Building and Construction

2. Chemistry and Chemical

3. Marine

4. Infrastructure

5. Automotive

![]()

| Product Code | Area Weight(g/m2) | Typical Width(mm) | Resin Compatibility | Product Features | Data Download |

| P02 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | High tensile strength, suitable for use in hand lay-up process to produce large-area parts, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength of composite products, superior acid corrosion resistance | P02 DATA |

| P20 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | Soft mat, ease of manual tearing apart, good conformabilit, good wet-through and fast wet-out in resins, rapid air release reducing rolling out times and increasing productivity, low resin consumption, high mechanical strength of composite products, superior acid corrosion resistance | P20 DATA |

Powder Chopped Strand Mats:

Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins.The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time can be available upon request.

![]()

Mat Production Process:

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

![]()

1. Building and Construction

2. Chemistry and Chemical

3. Marine

4. Infrastructure

5. Automotive

![]()

| Product Code | Area Weight(g/m2) | Typical Width(mm) | Resin Compatibility | Product Features | Data Download |

| P02 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | High tensile strength, suitable for use in hand lay-up process to produce large-area parts, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength of composite products, superior acid corrosion resistance | P02 DATA |

| P20 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | Soft mat, ease of manual tearing apart, good conformabilit, good wet-through and fast wet-out in resins, rapid air release reducing rolling out times and increasing productivity, low resin consumption, high mechanical strength of composite products, superior acid corrosion resistance | P20 DATA |