Emulsion Chopped Strand Mats are made of randomly distributed chopped strands held together by an emulsion binder. They are compatible with UP and VE resins. The roll width ranges from 200mm to 3,120mm. Special requirements may be available upon request.

Emulsion Chopped Strand Mats:

Emulsion Chopped Strand Mats are made of randomly distributed chopped strands held together by an emulsion binder. They are compatible with UP and VE resins. The roll width ranges from 200mm to 3,120mm. Special requirements may be available upon request.

![]()

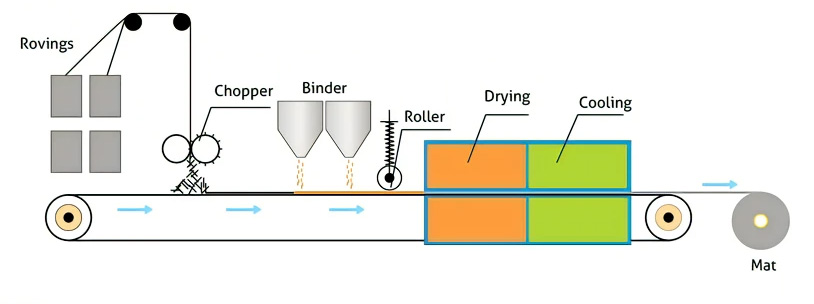

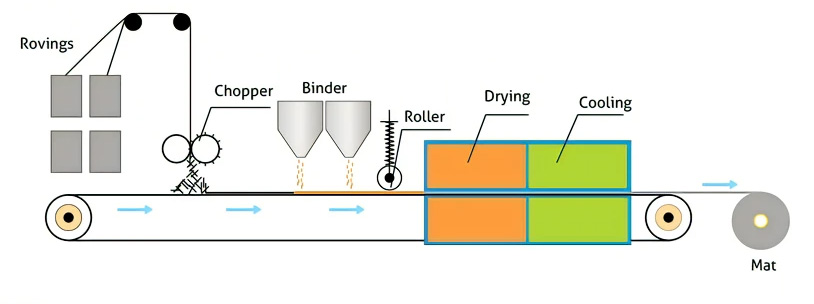

Mat Production Process:

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

![]()

1. Marine

2. Bathroom equipment

3. Automotive

4. Chemistry and Chemical

5. Sports and Leisure

![]()

| Product Code | Area Weight (gm2) | Typical Width (mm) | Resin Compatibility | Product Features | Data Download |

| E01 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE | High tensile strength, allowing for use in hand lay-up process to produce large-area parts, no airborne fiber when operating, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength, superior acid corrosion resistance | E01 DATA |

| E10 | Rapid air lease reducing rolling out times, low resin consumption | E10 DATA | |||

| E20 | Good moldability, good wet-through and fast wet-out in resins, rapid air lease reducing rolling out times and increasing productivity, low resin consumption, high mechanical strength of composite products, superior acid corrosion resistance | E20 DATA |

Emulsion Chopped Strand Mats:

Emulsion Chopped Strand Mats are made of randomly distributed chopped strands held together by an emulsion binder. They are compatible with UP and VE resins. The roll width ranges from 200mm to 3,120mm. Special requirements may be available upon request.

![]()

Mat Production Process:

Assembled rovings are chopped to a specified length, and then fall onto a conveyor randomly. The chopped strands are bonded together by either an emulsion binder or a powder binder. After drying, cooling and winding, a chopped stand mat is formed.

![]()

1. Marine

2. Bathroom equipment

3. Automotive

4. Chemistry and Chemical

5. Sports and Leisure

![]()

| Product Code | Area Weight (gm2) | Typical Width (mm) | Resin Compatibility | Product Features | Data Download |

| E01 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE | High tensile strength, allowing for use in hand lay-up process to produce large-area parts, no airborne fiber when operating, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength, superior acid corrosion resistance | E01 DATA |

| E10 | Rapid air lease reducing rolling out times, low resin consumption | E10 DATA | |||

| E20 | Good moldability, good wet-through and fast wet-out in resins, rapid air lease reducing rolling out times and increasing productivity, low resin consumption, high mechanical strength of composite products, superior acid corrosion resistance | E20 DATA |