Compofil® is thermoplastic prepreg made from continuous fiberglass coated with thermoplastics. It is specially designed to manufacture high performance composite components directly with no need for extra resin. It is suitable for various composite processes including compression molding, vacuum molding, filament winding, pultrusion etc., widely applied in aerospace, automotive, construction, sports and new energy industry.

High Performance Hybrid Fiber:

Compofil® is thermoplastic prepreg made from continuous fiberglass coated with thermoplastics. It is specially designed to manufacture high performance composite components directly with no need for extra resin. It is suitable for various composite processes including compression molding, vacuum molding, filament winding, pultrusion etc., widely applied in aerospace, automotive, construction, sports and new energy industry.

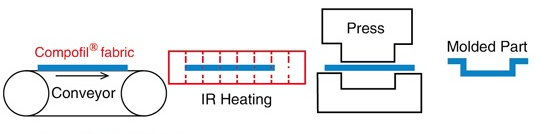

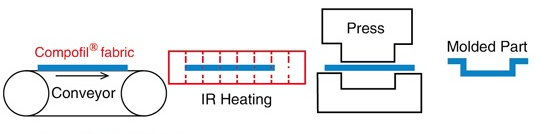

Mold Pressing:

Sheets of fabric as designed unidirectional, plain, twill and satin are placed, then heated to reactivate itself and pressed rapidly in the mold, to form the composite parts.

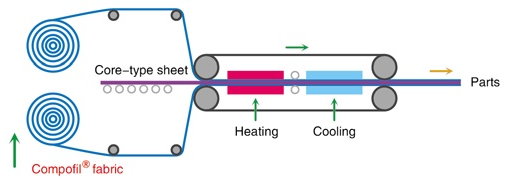

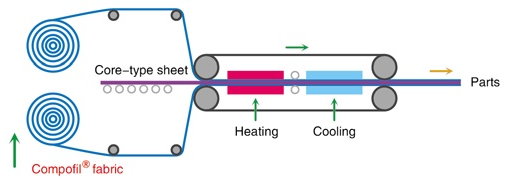

Laminate Molding:

Sheets of fabric as designed are placed on the mold according to design requirements, then put into the laminate machine to reactivate itself; The end parts are got by the cooling process; The molding process is continous with high productivity suitable for mass production.

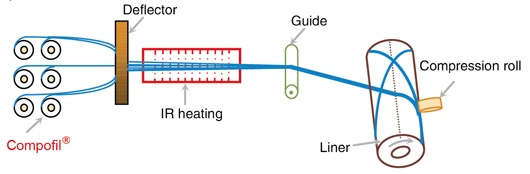

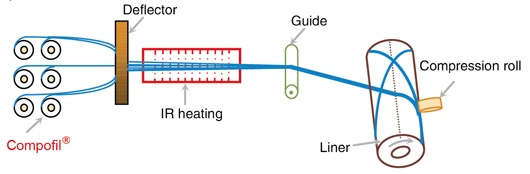

Filament Winding:

Filament Winding is an automated open molding process that uses a ratation mandrel and a compression roll as the mold. Compofil® are drawn through a deflector and pulled by the force of a rotating mandrel. After Compofil is heated to reactivate, the roving is wound around the mold, forming the composite parts. Filament winding is used to deliver high strength, specifically important for various applications, such as gas tanks, pipes and so on.

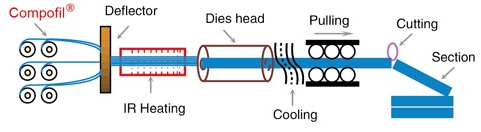

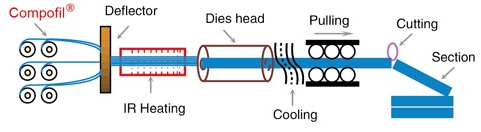

Pultrusion:

The Compofil® is pulled by the traction device, through the guide roller, IR heating device and the mold forming, and then finally cooled, cut to form the final products. The process is suitable for high-strength applications such as dooe frames, fiber reinforced core, and so on.

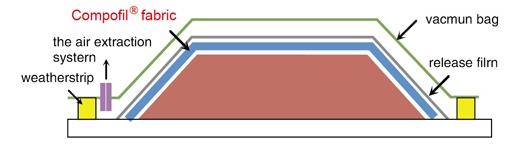

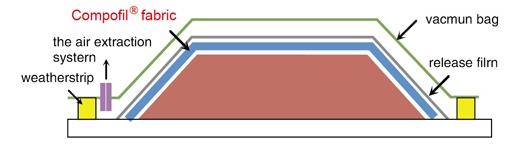

Vacuum-Assisted Molding:

Compofil® fabric is spread onto the mold with mold release film, then covered with the release film and a vacuum bag in order, consisting the air extraction system and getting a negative pressure; then the mold is heated and finally the final product is obtained after cooling.

1. Aerospace

2. Automotive

3. Building

4. Sports

5. New Energy

| Product Code | Nominal Linear Density(tex) | Resin Compatibility | Product Features | Typical Application | Data Download |

| 354 | 1870, 800 | PP | Hybrid fiber with PP, good impregnation, excellent mechanical properties, suitable for compression molding process | Moulding board | 354 DATA |

| 354A | 1870 | PP | Hybrid fiber with PP, good mechanical properties, excellent fatigue resistance,suitable for winding process | Winding pipe | 354A DATA |

| 356 | 2690 | PET | Hybrid fiber with PET, good impregnation, excellent mechanical properties, suitable for pultrusion process | Pultrusion profiles | 356 DATA |

High Performance Hybrid Fiber:

Compofil® is thermoplastic prepreg made from continuous fiberglass coated with thermoplastics. It is specially designed to manufacture high performance composite components directly with no need for extra resin. It is suitable for various composite processes including compression molding, vacuum molding, filament winding, pultrusion etc., widely applied in aerospace, automotive, construction, sports and new energy industry.

Mold Pressing:

Sheets of fabric as designed unidirectional, plain, twill and satin are placed, then heated to reactivate itself and pressed rapidly in the mold, to form the composite parts.

Laminate Molding:

Sheets of fabric as designed are placed on the mold according to design requirements, then put into the laminate machine to reactivate itself; The end parts are got by the cooling process; The molding process is continous with high productivity suitable for mass production.

Filament Winding:

Filament Winding is an automated open molding process that uses a ratation mandrel and a compression roll as the mold. Compofil® are drawn through a deflector and pulled by the force of a rotating mandrel. After Compofil is heated to reactivate, the roving is wound around the mold, forming the composite parts. Filament winding is used to deliver high strength, specifically important for various applications, such as gas tanks, pipes and so on.

Pultrusion:

The Compofil® is pulled by the traction device, through the guide roller, IR heating device and the mold forming, and then finally cooled, cut to form the final products. The process is suitable for high-strength applications such as dooe frames, fiber reinforced core, and so on.

Vacuum-Assisted Molding:

Compofil® fabric is spread onto the mold with mold release film, then covered with the release film and a vacuum bag in order, consisting the air extraction system and getting a negative pressure; then the mold is heated and finally the final product is obtained after cooling.

1. Aerospace

2. Automotive

3. Building

4. Sports

5. New Energy

| Product Code | Nominal Linear Density(tex) | Resin Compatibility | Product Features | Typical Application | Data Download |

| 354 | 1870, 800 | PP | Hybrid fiber with PP, good impregnation, excellent mechanical properties, suitable for compression molding process | Moulding board | 354 DATA |

| 354A | 1870 | PP | Hybrid fiber with PP, good mechanical properties, excellent fatigue resistance,suitable for winding process | Winding pipe | 354A DATA |

| 356 | 2690 | PET | Hybrid fiber with PET, good impregnation, excellent mechanical properties, suitable for pultrusion process | Pultrusion profiles | 356 DATA |