Power Chopped Strand Mat is made of randomly distruted chopped strands held together by a powder binder. It is compatible with UP, VE, and EP resins. The roll width ranges from 200mm to 3,120mm.

Power Chopped Strand Mat :

Power Chopped Strand Mat is made of randomly distruted chopped strands held together by a powder binder. It is compatible with UP, VE, and EP resins. The roll width ranges from 200mm to 3,120mm.

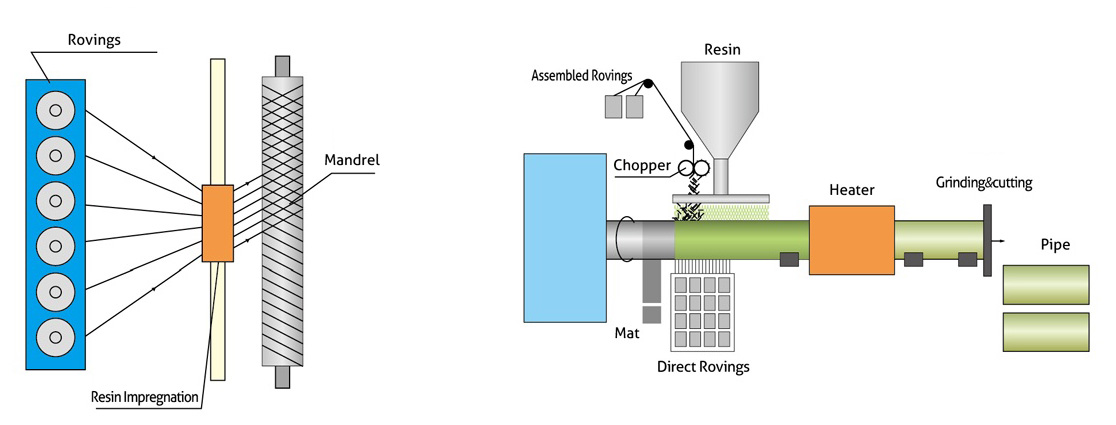

Traditonal Filament Winding:

In the fialment winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

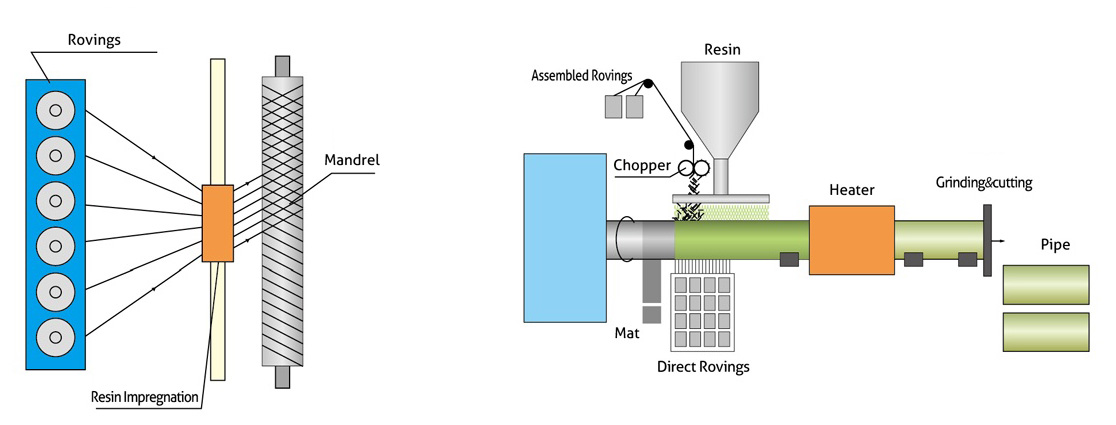

Continuous Filament Winding :

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

1. Chemistry and Chemical

2. Infrastructure

3. Marine

4. Petrochemical

5. Building and Construction

| Product Code | Area Weight(g/m2) | Typical Width(mm) | Resin Compatibility | Product Features | Data Download |

| P02 | 225, 300, 450 | 1040, 1270 | UP, VE, EP | High tensile strength, suitable for use in hand lay-up process to produce large-area parts, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength of composite products, superior acid corrosion resistance | P02 DATA |

Power Chopped Strand Mat :

Power Chopped Strand Mat is made of randomly distruted chopped strands held together by a powder binder. It is compatible with UP, VE, and EP resins. The roll width ranges from 200mm to 3,120mm.

Traditonal Filament Winding:

In the fialment winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

Continuous Filament Winding :

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

1. Chemistry and Chemical

2. Infrastructure

3. Marine

4. Petrochemical

5. Building and Construction

| Product Code | Area Weight(g/m2) | Typical Width(mm) | Resin Compatibility | Product Features | Data Download |

| P02 | 225, 300, 450 | 1040, 1270 | UP, VE, EP | High tensile strength, suitable for use in hand lay-up process to produce large-area parts, good wet-through and fast wet-out in resins, rapid air lease, high mechanical strength of composite products, superior acid corrosion resistance | P02 DATA |