Assembled Rovings for Chopping are coated with a special silane-based sizing and compatible with UP and VE resins. They are designed for pipe production, offering excellent water resistance and chemical corrosion resistance.

Assembled Rovings for Chopping :

Assembled Rovings for Chopping are coated with a special silane-based sizing and compatible with UP and VE resins. They are designed for pipe production, offering excellent water resistance and chemical corrosion resistance.

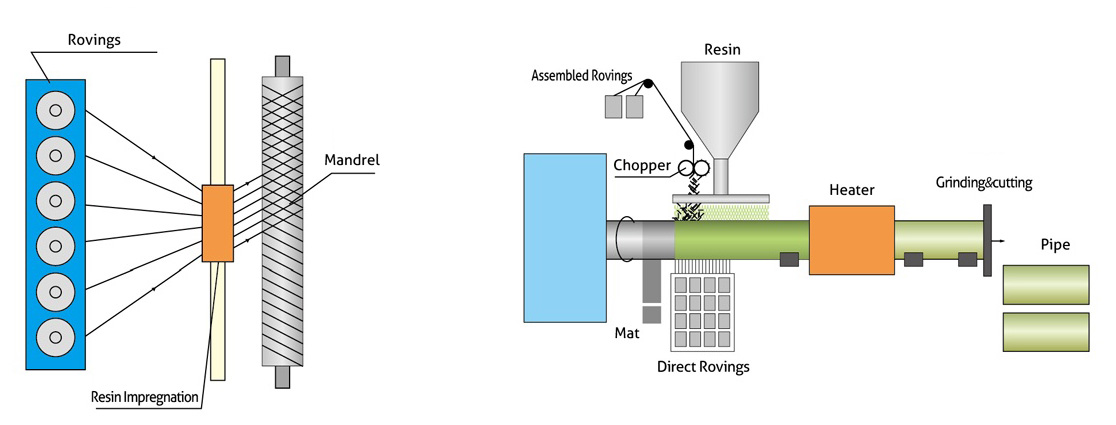

Traditonal Filament Winding:

In the fialment winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

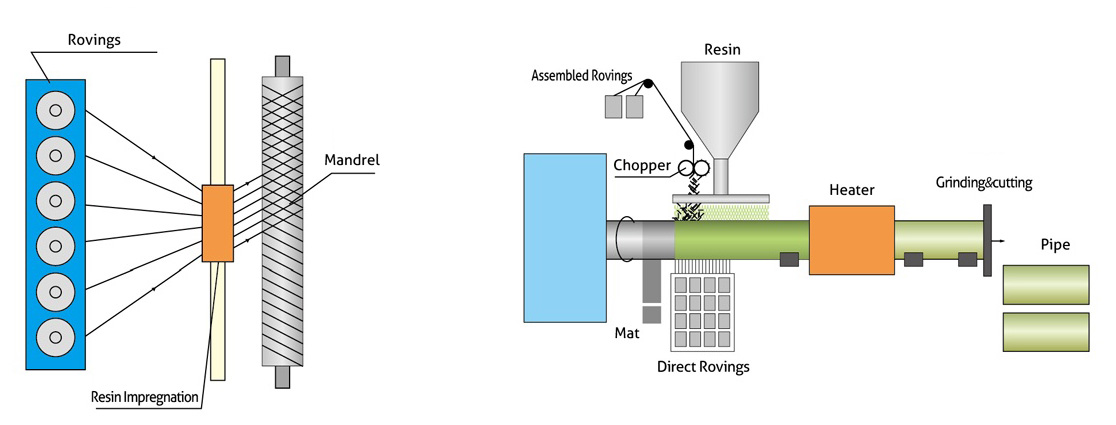

Continuous Filament Winding :

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

1. Chemistry and Chemical

2. Infrastructure

3. Marine

4. Petrochemical

5. Building and Construction

| Product Code | Resin Compatibility | Product Features | Typical Application | Data Download |

| 162 | UP,VE | Moderate wet-out | Continuous filament wound pipes | 162 DATA |

| 162K | UP,VE | Fast wet-out | Continuous filament wound pipes | 162K DATA |

| 162E | EP | Compatible with epoxy resin,highmechanical strength of composite products. | Continuous filament wound pipes | 162E DATA |

Assembled Rovings for Chopping :

Assembled Rovings for Chopping are coated with a special silane-based sizing and compatible with UP and VE resins. They are designed for pipe production, offering excellent water resistance and chemical corrosion resistance.

Traditonal Filament Winding:

In the fialment winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

Continuous Filament Winding :

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

1. Chemistry and Chemical

2. Infrastructure

3. Marine

4. Petrochemical

5. Building and Construction

| Product Code | Resin Compatibility | Product Features | Typical Application | Data Download |

| 162 | UP,VE | Moderate wet-out | Continuous filament wound pipes | 162 DATA |

| 162K | UP,VE | Fast wet-out | Continuous filament wound pipes | 162K DATA |

| 162E | EP | Compatible with epoxy resin,highmechanical strength of composite products. | Continuous filament wound pipes | 162E DATA |