Assembled Roving for Filament Winding is specially designed for FRP filament winding process and compatible with UP, EP and VE resins.Its final composite product delivers excellent mechanical properties.

Assembled Roving for Filament Winding :

Assembled Roving for Filament Winding is specially designed for FRP filament winding process and compatible with UP, EP and VE resins.Its final composite product delivers excellent mechanical properties.

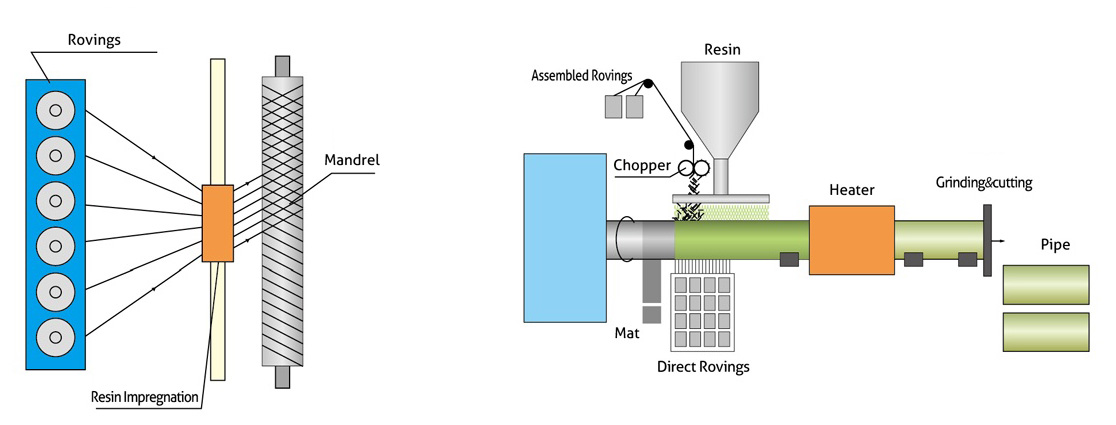

Traditonal Filament Winding:

In the fialment winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

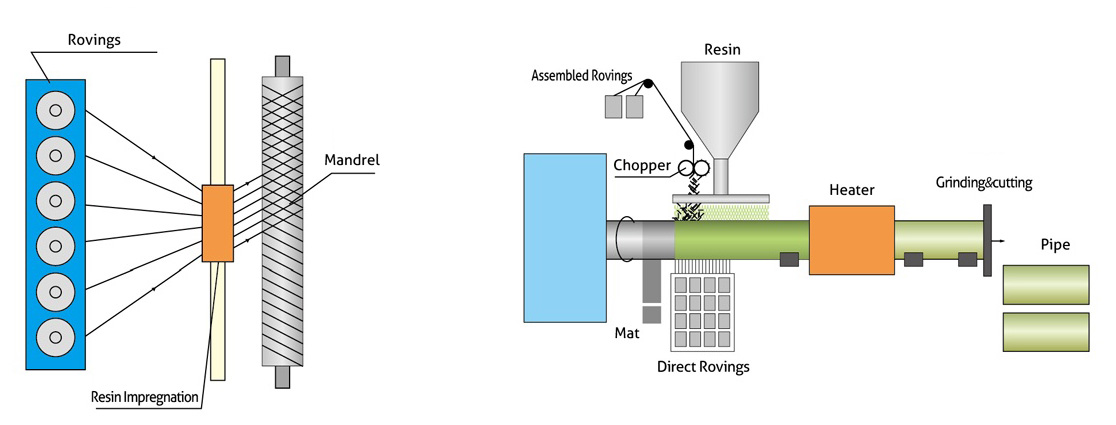

Continuous Filament Winding :

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

1. Chemistry and Chemical

2. Infrastructure

3. Marine

4. Petrochemical

5. Building and Construction

| Product Code | Resin Compatibility | Product Features | Typical Application | Data Download |

| 266 | UP | Fast wet-out, low fuzz and high strength | Pipes and storage tanks | 266 DATA |

Assembled Roving for Filament Winding :

Assembled Roving for Filament Winding is specially designed for FRP filament winding process and compatible with UP, EP and VE resins.Its final composite product delivers excellent mechanical properties.

Traditonal Filament Winding:

In the fialment winding process, continuous strands of resin-impregnated glass fiber are wound under tension onto a mandrel in precise geometric patterns to build up the part which is then cured to form the finished parts.

Continuous Filament Winding :

Multiple laminate layers, composed of resin, reinforcement glass and other materials are applied to a rotating mandrel, which is formed from a continuous steel band continuously traveling in a cork-screw motion. The composite part is heated and cured in place as the mandrel travels through the line and then cut into a specific length with a traveling cut-off saw.

1. Chemistry and Chemical

2. Infrastructure

3. Marine

4. Petrochemical

5. Building and Construction

| Product Code | Resin Compatibility | Product Features | Typical Application | Data Download |

| 266 | UP | Fast wet-out, low fuzz and high strength | Pipes and storage tanks | 266 DATA |