Assembled Rovings for LFI are compatible with PU and VE. They deliver properties of low static, excellent dispersion and good wet-out in resin.

Assembled Rovings for LFI :

Assembled Rovings for LFI are compatible with PU and VE. They deliver properties of low static, excellent dispersion and good wet-out in resin.

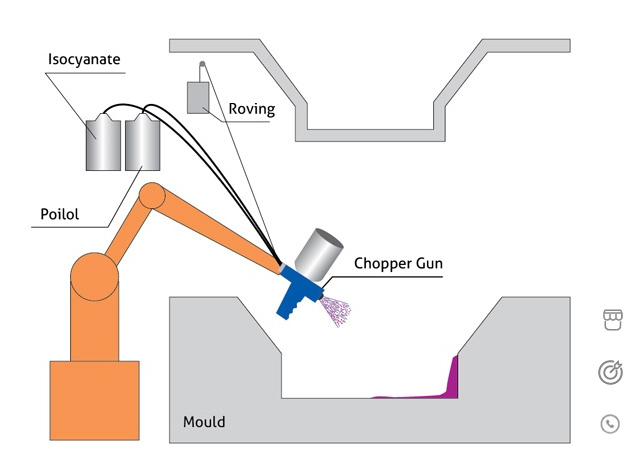

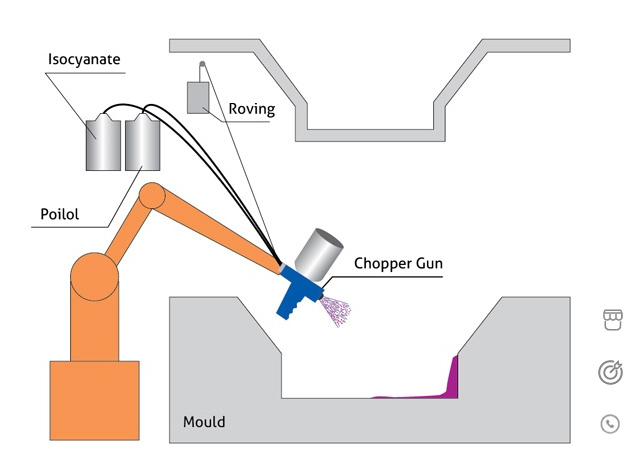

LFI Process:

The roving is chopped into certain length using a spraying machine. The isocyanate, poluol, and chopped strand mixture is sprayed onto an open mould. The mould is then closed, heated and pressure applied, and the part is cured.

1. Building

2. Marine

3. Automotive

| Product Code | Nominal Linear Density(tex) | Resin Compatibility | Product Features | Typical Application | Data Download |

| 440 | 2400,4400,4800 | UP,VE | Excellent choppability and dispersion, good mold flowability,high mechanical strength of composite products | Door skins, automotive parts | 440 DATA |

Assembled Rovings for LFI :

Assembled Rovings for LFI are compatible with PU and VE. They deliver properties of low static, excellent dispersion and good wet-out in resin.

LFI Process:

The roving is chopped into certain length using a spraying machine. The isocyanate, poluol, and chopped strand mixture is sprayed onto an open mould. The mould is then closed, heated and pressure applied, and the part is cured.

1. Building

2. Marine

3. Automotive

| Product Code | Nominal Linear Density(tex) | Resin Compatibility | Product Features | Typical Application | Data Download |

| 440 | 2400,4400,4800 | UP,VE | Excellent choppability and dispersion, good mold flowability,high mechanical strength of composite products | Door skins, automotive parts | 440 DATA |