Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time may be available upon request.

Powder Chopped Strand Mats :

Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time may be available upon request.

![]()

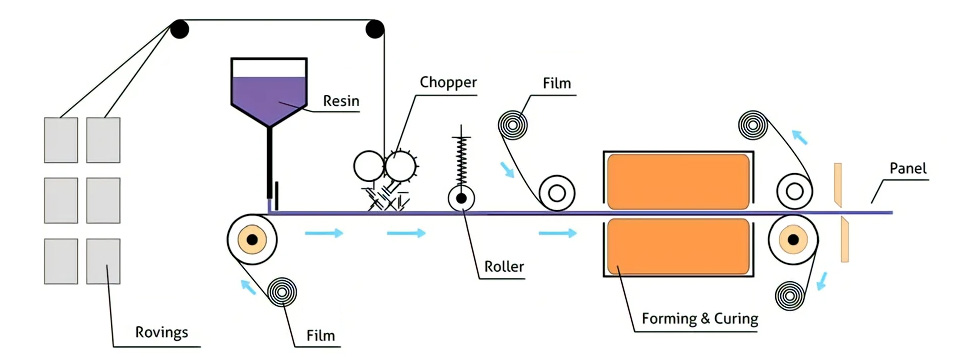

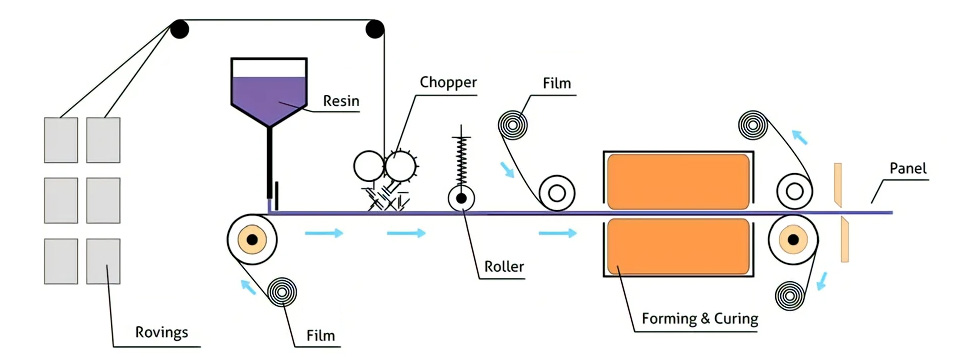

Continuous Panel Molding Process:

A resin mix is uniformly deposited in a controlled amount onto a moving film at a constant speed. The thickness of the resin is controlled by the draw-knife. Fiberglass roving is chopped and uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

![]()

1. Building and Construction

2. Automotive

3. Agriculture

4. Fiberglass Reinforced Polyester

![]()

| Product Code | Area Weight (g/m2) | Typical Width (mm) | Resin Compatibility | Typical Application | Data Download |

| P02 | 225, 300, 450, 600 | 1040, 1270 | UP, VE, EP | High tensile strength, good processing, suitable for use in semitransparent and opaque FRP panels | P02 DATA |

| P30 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | Fast wet-out, suitable for use in high translucent panels | P30 DATA |

Powder Chopped Strand Mats :

Powder Chopped Strand Mats are made of randomly distributed chopped strands held together by a powder binder. They are compatible with UP, VE, EP and PF resins. The roll width ranges from 200mm to 3,120mm. Additional demands on wet-out and decomposition time may be available upon request.

![]()

Continuous Panel Molding Process:

A resin mix is uniformly deposited in a controlled amount onto a moving film at a constant speed. The thickness of the resin is controlled by the draw-knife. Fiberglass roving is chopped and uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

![]()

1. Building and Construction

2. Automotive

3. Agriculture

4. Fiberglass Reinforced Polyester

![]()

| Product Code | Area Weight (g/m2) | Typical Width (mm) | Resin Compatibility | Typical Application | Data Download |

| P02 | 225, 300, 450, 600 | 1040, 1270 | UP, VE, EP | High tensile strength, good processing, suitable for use in semitransparent and opaque FRP panels | P02 DATA |

| P30 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | Fast wet-out, suitable for use in high translucent panels | P30 DATA |