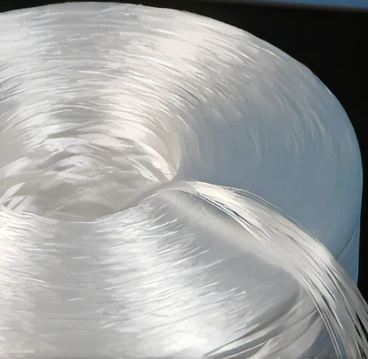

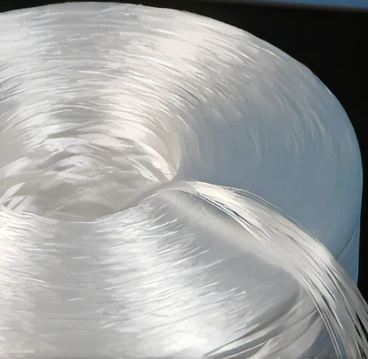

Assembled Pannel Rovings are coated with a silane-based sizing and compatible with UP and acrylic resins. They can fast wet-out in resin and deliver excellent dispersion after chopping.

Assembled Pannel Rovings :

Assembled Pannel Rovings are coated with a silane-based sizing and compatible with UP and acrylic resins. They can fast wet-out in resin and deliver excellent dispersion after chopping.

![]()

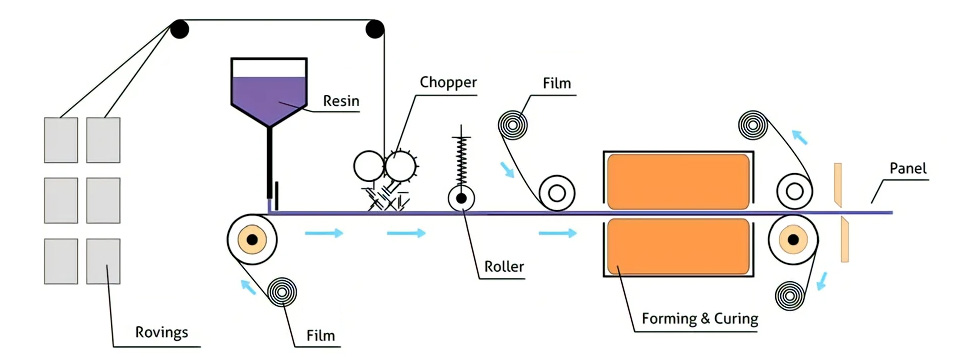

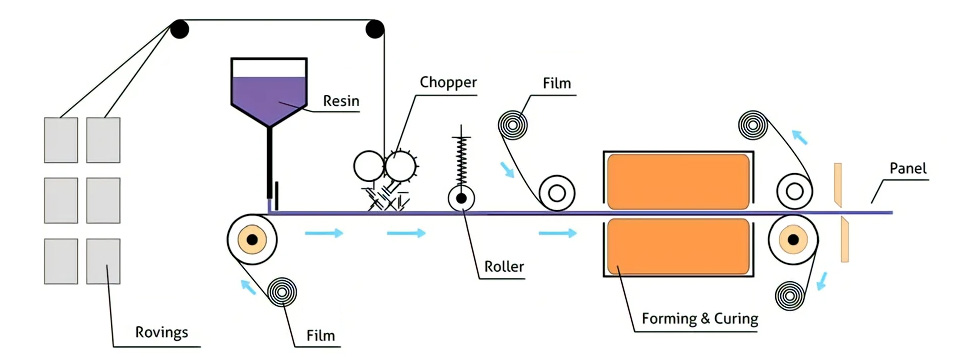

Continuous Panel Molding Process:

A resin mix is uniformly deposited in a controlled amount onto a moving film at a constant speed. The thickness of the resin is controlled by the draw-knife. Fiberglass roving is chopped and uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

![]()

1. Building and Construction

2. Automotive

3. Agriculture

4. Fiberglass Reinforced Polyester

![]()

| Product Code | Nominal Linear Density (tex) | Resin Compatibility | Product Features | Typical Application | Data Download |

| 838 | 2400,3200,4800 | UP | Low static, fast wet-out, no white fibers | General purpose transparent FRP panels | 838 DATA |

| 872 | UP, PM, MA | Extremely fast wet-out, no white fibers, superior transparency | High transparency FRP panels | 872 DATA | |

| 872S | UP, PM, MA | Low static, moderate wet-out, excellent dispersion after chopping under low tension | Semitransparent and opaque FRP panels | 872S DATA |

Assembled Pannel Rovings :

Assembled Pannel Rovings are coated with a silane-based sizing and compatible with UP and acrylic resins. They can fast wet-out in resin and deliver excellent dispersion after chopping.

![]()

Continuous Panel Molding Process:

A resin mix is uniformly deposited in a controlled amount onto a moving film at a constant speed. The thickness of the resin is controlled by the draw-knife. Fiberglass roving is chopped and uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

![]()

1. Building and Construction

2. Automotive

3. Agriculture

4. Fiberglass Reinforced Polyester

![]()

| Product Code | Nominal Linear Density (tex) | Resin Compatibility | Product Features | Typical Application | Data Download |

| 838 | 2400,3200,4800 | UP | Low static, fast wet-out, no white fibers | General purpose transparent FRP panels | 838 DATA |

| 872 | UP, PM, MA | Extremely fast wet-out, no white fibers, superior transparency | High transparency FRP panels | 872 DATA | |

| 872S | UP, PM, MA | Low static, moderate wet-out, excellent dispersion after chopping under low tension | Semitransparent and opaque FRP panels | 872S DATA |