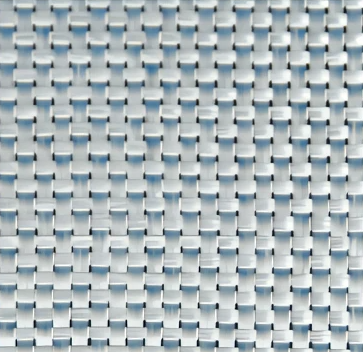

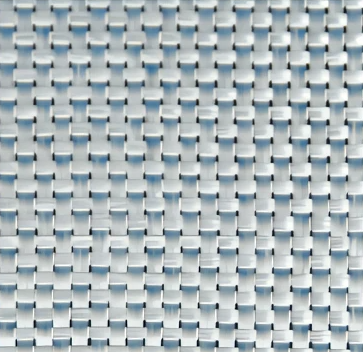

Woven Rovings are compatible with UP, VE, EP and PF resins. Woven Rovings are available with a width range of 50mm ~ 3,000mm and a weight range of 260g/m2 ~ 1,600g/m2. Other specifications are also available on customer request.

Woven Rovings:

Woven Rovings are compatible with UP, VE, EP and PF resins. Woven Rovings are available with a width range of 50mm ~ 3,000mm and a weight range of 260g/m2 ~ 1,600g/m2. Other specifications are also available on customer request.

![]()

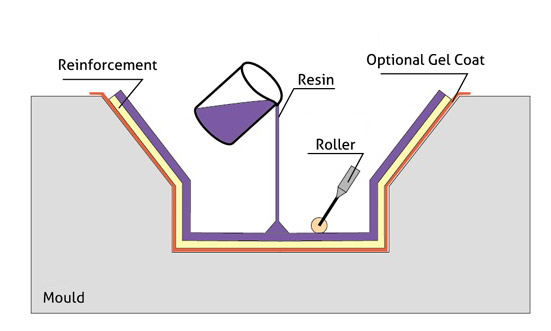

Hand Lay-up Process:

The reinforcement, in front of hiberglass strands, mat or woven roving, is first laid into a mold which has been coated with a release agent and a gelcoat. Then a resin mix is applied by hand using a brush or spray gun. A roller is then used to ensure uniform impregnation, complete glass wet-out, and removal of any trapped air bubbles. This operation is repeated until the desired thickness of the structure is obtained. After curing at toom temperature or under heating conditions, the finished parts are formed.

![]()

1. Marine

2. Bathroom equipment

3. Automotive

4. Chemistry and Chemical

5. Sports and Leisure

![]()

| Certification | Product Code | Certificate No |

| DNV | EWR270 | TAK00001TH |

| EWR360 | ||

| EWR580 | ||

| EWR600 | ||

| EWR800 | ||

| LR | EWR270 | LR2002408ALP |

| EWR360 | LR2002409ALP | |

| EWR580 | LR2002410ALP | |

| EWR600 | LR2002411ALP | |

| EWR800 | LR2002412ALP |

Woven Rovings:

Woven Rovings are compatible with UP, VE, EP and PF resins. Woven Rovings are available with a width range of 50mm ~ 3,000mm and a weight range of 260g/m2 ~ 1,600g/m2. Other specifications are also available on customer request.

![]()

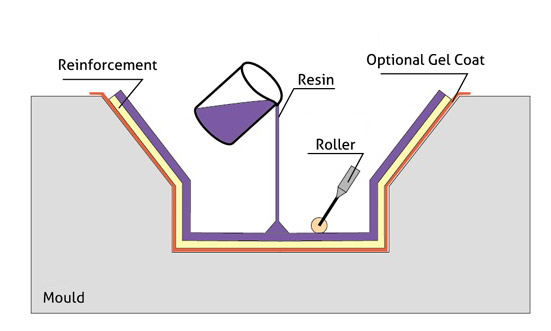

Hand Lay-up Process:

The reinforcement, in front of hiberglass strands, mat or woven roving, is first laid into a mold which has been coated with a release agent and a gelcoat. Then a resin mix is applied by hand using a brush or spray gun. A roller is then used to ensure uniform impregnation, complete glass wet-out, and removal of any trapped air bubbles. This operation is repeated until the desired thickness of the structure is obtained. After curing at toom temperature or under heating conditions, the finished parts are formed.

![]()

1. Marine

2. Bathroom equipment

3. Automotive

4. Chemistry and Chemical

5. Sports and Leisure

![]()

| Certification | Product Code | Certificate No |

| DNV | EWR270 | TAK00001TH |

| EWR360 | ||

| EWR580 | ||

| EWR600 | ||

| EWR800 | ||

| LR | EWR270 | LR2002408ALP |

| EWR360 | LR2002409ALP | |

| EWR580 | LR2002410ALP | |

| EWR600 | LR2002411ALP | |

| EWR800 | LR2002412ALP |