Assembled Roving for GMT:

GMT non alkali glass fiber roving is made of special sizing agent, which has good compatibility with modified PP resin, moderate fiber stiffness, excellent band forming and dispersion, and can give the composite excellent mechanical and electrical properties.

![]()

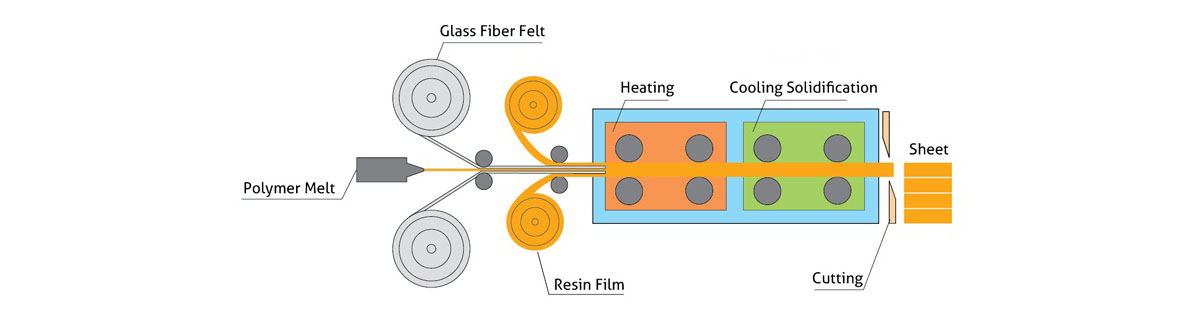

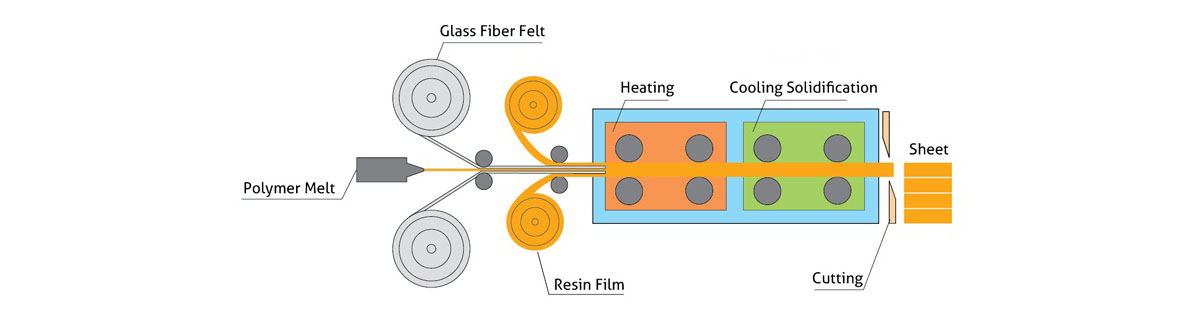

GMT Process:

Generally two layers of reinforcing mat are sandwiched between three layers of polypropylene, which is then heated and consolidated into a semi-finished sheet product.The semi-finished sheets are then heated and molded by stamping or compression process to make complex finished parts.

![]()

1. Building Materials

2. Automobiles

3. Trucks

![]()

| Product Code | Filament Diameter (μm) | Resin Compatibility | Product Features | Data Download |

| 522 | 13 | PP | Assembled roving for GMT-RD, excellent choppability | 522 DATA |

Assembled Roving for GMT:

GMT non alkali glass fiber roving is made of special sizing agent, which has good compatibility with modified PP resin, moderate fiber stiffness, excellent band forming and dispersion, and can give the composite excellent mechanical and electrical properties.

![]()

GMT Process:

Generally two layers of reinforcing mat are sandwiched between three layers of polypropylene, which is then heated and consolidated into a semi-finished sheet product.The semi-finished sheets are then heated and molded by stamping or compression process to make complex finished parts.

![]()

1. Building Materials

2. Automobiles

3. Trucks

![]()

| Product Code | Filament Diameter (μm) | Resin Compatibility | Product Features | Data Download |

| 522 | 13 | PP | Assembled roving for GMT-RD, excellent choppability | 522 DATA |