Coated with silane-based agents, our glass roving for thermoplastics are ideal options for reinforcing many resin systems such as PA, PBT, PET, PP, ABS, AS and PC. The roving have excellent processability and dispersion, imparting outstanding physiacl and mechanical properties to the composite products.

Roving For Thermoplastics:

Coated with silane-based agents, our glass roving for thermoplastics are ideal options for reinforcing many resin systems such as PA, PBT, PET, PP, ABS, AS and PC. The roving have excellent processability and dispersion, imparting outstanding physiacl and mechanical properties to the composite products.

Extrusion and Injection Process:

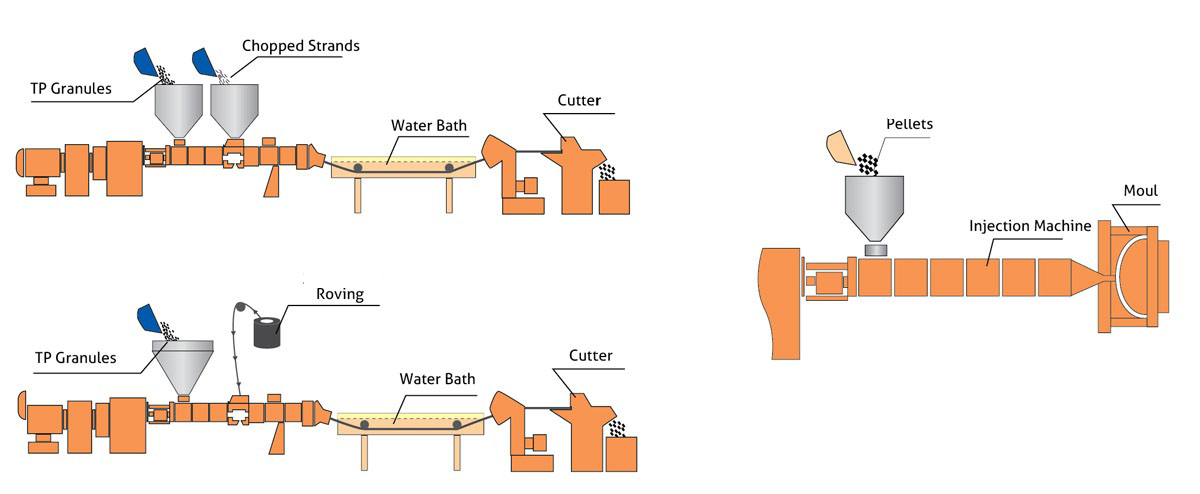

The reinforcements(glass fiber roving or chopped strands) and thermoplastic resin are mixed in an extruder. After cooling, they are chopped into reinforced thermoplastic pellets. The pellets are fed into an injection molding machine to form finished parts.

1. Automotive

2. Consumer Goods and Business Equipment

3. Sports and Leisure

4. Electrical and Electronics

5. Building and Construction

6. Infrastructure

| Product Code | Filament Diameter(μm) | Nominal Linear Density(tex) | Resin Compatibility and Reinforcement Effect | Product Features | Data Download | |||

| PA | PBT,PET | AS,ABS | PP | |||||

| 910 | 13 | 2000 | ★ | ○ | ○ | ★ | Excellent Hydrolysis Resistance | 910 DATA |

| 960A | 14,17 | 2000,2400 | ☆ | ☆ | ★ | ★ | High Performance, Low Hairiness | 960A DATA |

| 988A | 13,14 | 1000,2000 | ★ | ★ | ★ | ○ | Standard Product Certified to FDA | 988A DATA |

| Remarks: ★Best; ☆Good; ○Simple | ||||||||

Roving For Thermoplastics:

Roving For Thermoplastics:

Assembled Roving for Spray-up are compatible with UP, VE and PU resin. They deliverproperties![]() of low static, excellent dispersion and good wet-out in resins.

of low static, excellent dispersion and good wet-out in resins.

Extrusion and Injection Process:

The reinforcements(glass fiber roving or chopped strands) and thermoplastic resin are mixed in an extruder. After cooling, they are chopped into reinforced thermoplastic pellets. The pellets are fed into an injection molding machine to form finished parts.

1. Automotive

1. Automotive

2. Consumer Goods and Business Equipment

3. Sports and Leisure

4. Electrical and Electronics

5. Building and Construction

6. Infrastructure

| Product Code | Product Features | Data Download |

| 910 | Excellent Hydrolysis Resistance | 910 DATA |

| 960A | High Performance, Low Hairiness | 960A DATA |

| 988A | Standard Product, Fda Certified | 988A DATA |