Assembled Roving for Spray-up are compatible with UP, VE and PU resin. They deliver properties of low static, excellent dispersion and good wet-out in resins.

Assembled Roving for Spray-up:

Assembled Roving for Spray-up are compatible with UP, VE and PU resin. They deliver properties![]() of low static, excellent dispersion and good wet-out in resins.

of low static, excellent dispersion and good wet-out in resins.

![]()

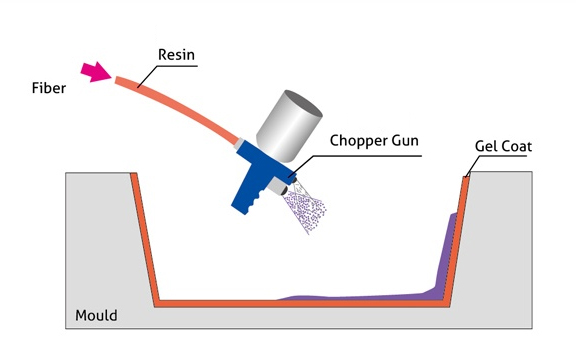

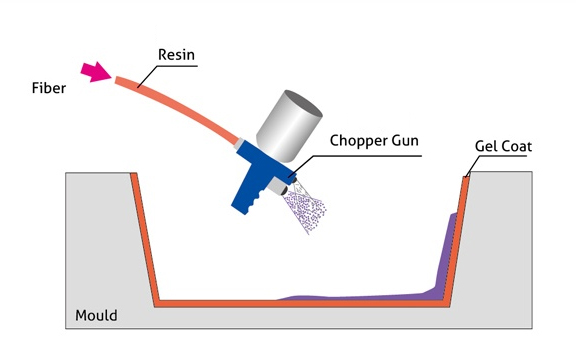

Spray-up Process:

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving(fiberglass cut to specific length using a chopper gun). Then the glass-resin mixture is well compacted, usually manually, for complete impregnation and deairing. After curing the finished composite part is de-molded.

![]()

1. Marine

2. Bathroom equipment

3. Automotive

4. Chemistry and Chemical

5. Sports and Leisure

![]()

| Product Code | Nominal Linear Density (tex) | Product Features | Typical Application | Data Download |

| 176 | 2400, 3460, 4800 | Good runnability for spraying operation, larger dispersion area in spraying, slower wet-out, less slide on vertical surfaces, suitable for production of large parts | Swimming pools, storage tanks,boats & yachts | 176 DATA |

| 180 | Good runnability for spraying operation, moderate wet-out speed, easy roll-out, easy removal of bubbles,no spring back in sharp angles, excellent mechanical properties and hydrolytic resistance in parts, suitable for high-speed spray-up process with robots | Sanitary ware, FRP hulls, auto parts, chemical storage tanks | 180 DATA | |

| 180K | Fast wet-out,ideal for products with small surface | Bathtubs | 180K DATA |

Assembled Roving for Spray-up:

Assembled Roving for Spray-up are compatible with UP, VE and PU resin. They deliver properties![]() of low static, excellent dispersion and good wet-out in resins.

of low static, excellent dispersion and good wet-out in resins.

![]()

Spray-up Process:

A mould is sprayed with a mixture of catalyzed resin and chopped fiberglass roving(fiberglass cut to specific length using a chopper gun). Then the glass-resin mixture is well compacted, usually manually, for complete impregnation and deairing. After curing the finished composite part is de-molded.

![]()

1. Marine

2. Bathroom equipment

3. Automotive

4. Chemistry and Chemical

5. Sports and Leisure

![]()

| Product Code | Nominal Linear Density (tex) | Product Features | Typical Application | Data Download |

| 176 | 2400, 3460, 4800 | Good runnability for spraying operation, larger dispersion area in spraying, slower wet-out, less slide on vertical surfaces, suitable for production of large parts | Swimming pools, storage tanks,boats & yachts | 176 DATA |

| 180 | Good runnability for spraying operation, moderate wet-out speed, easy roll-out, easy removal of bubbles,no spring back in sharp angles, excellent mechanical properties and hydrolytic resistance in parts, suitable for high-speed spray-up process with robots | Sanitary ware, FRP hulls, auto parts, chemical storage tanks | 180 DATA | |

| 180K | Fast wet-out,ideal for products with small surface | Bathtubs | 180K DATA |